3D Concrete Printing Technology: Accurate, Real-Time Monitoring

Take full on-site control of the printing process. X-Hab 3D concrete printing technology establishes accuracy and efficiency at any job site on Earth.

What Is X-Hab 3D Printing Concrete Technology?

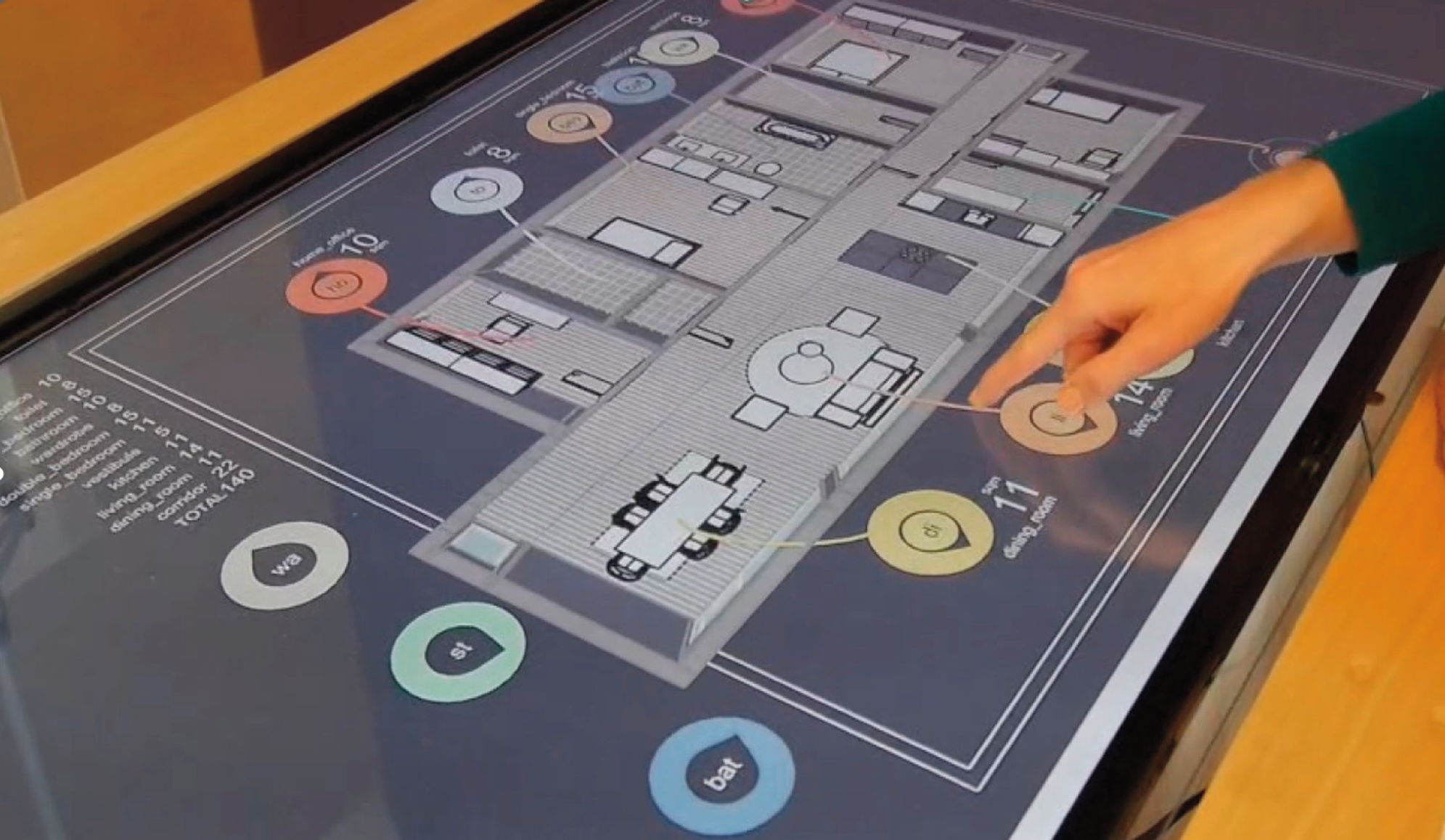

Most 3D concrete printers come with software. With X-Hab 3D, you gain an entire ecosystem of rigorous, yet easy-to-use scientific tools for mastering quality in the concrete printing process.

- Adjust mix on-site

- Adjust geometry while keeping structural integrity

- Free up weeks of capacity per build

When you start to build, the data updates in real time, verifying accuracy and minimizing the need for human intervention. Our printing systems adjust for the conditions to optimize concrete usage to your design, performance, and code requirements.

.jpg)

Why Use X-Hab 3D Concrete Printing Control Software?

Integrated

Our 3D-printed building technology is part of a complete ecosystem of X-Hab 3D hardware, software, and materials. All three combine seamlessly for the ultimate in quality, agility, and durability – in any environment.

Easy to Use

It’s hard to find skilled labor, so our software comes with a short learning curve and no need for robotics expertise. For the entire printing process, we offer training, 24/7 support, and courses co-developed with Penn State.

Customizable

Our concrete structure design software offers more design freedom than stick-built homes, including dimensions, textures, and colors. If your use case is unique, we can develop and test custom software.

Built for Your Industry

Whether your job is residential, commercial, or government, our 3D concrete printing software can solve for labor challenges and business growth. It meets both the extreme challenges of military applications and the basic needs of low-cost housing.

Accurate

The building design software deftly supports additive construction, with algorithms to predict structural behavior and compensate for material deformation. X-Hab 3D tools guarantee precision, shape, and stability.

Low-Cost, Low-Footprint

3D concrete design software saves 40-60% in materials and labor vs. stick-built construction. Repeatable and efficient, X-Hab 3D printing systems conserve natural resources and reduce your carbon footprint.

Technical Capabilities

Let's make your 3D concrete printing process as user-friendly as possible.

X-Hab 3D’s technology integrates all software and hardware necessary for the before, during, and after concrete 3D printing:

- Verifying design printability

- Live print monitoring

- Post-print analysis

We crafted this software with intuitive UIs to ensure ease of transition. It's compatible with Windows 10 and accepts stereolithography (.stl) file types.

Our software suite employs Rhino with the Grasshopper plugin, creating a dynamic workflow that unlocks the full potential of 3D concrete. This not only enhances precision in structural modeling, but also facilitates dynamic adjustments through parametric models. The flexibility extends to accepting G-code from third-party slicing software.

Proficiency is key, so the software allows you to generate toolpaths from initial designs, creating a user-controlled, customizable workflow. Print parameters are then optimized for the toolpath, giving you the ability to fine-tune preferences with precision.

To complement this, our exclusive Design Gallery is not only a repository of pre-designed structures, but also as a dynamic source of inspiration and innovation.

Work Smarter, Work Better

Start 3D concrete printing construction in a reliable and safe way. Invest in the X-Hab 3D ecosystem.