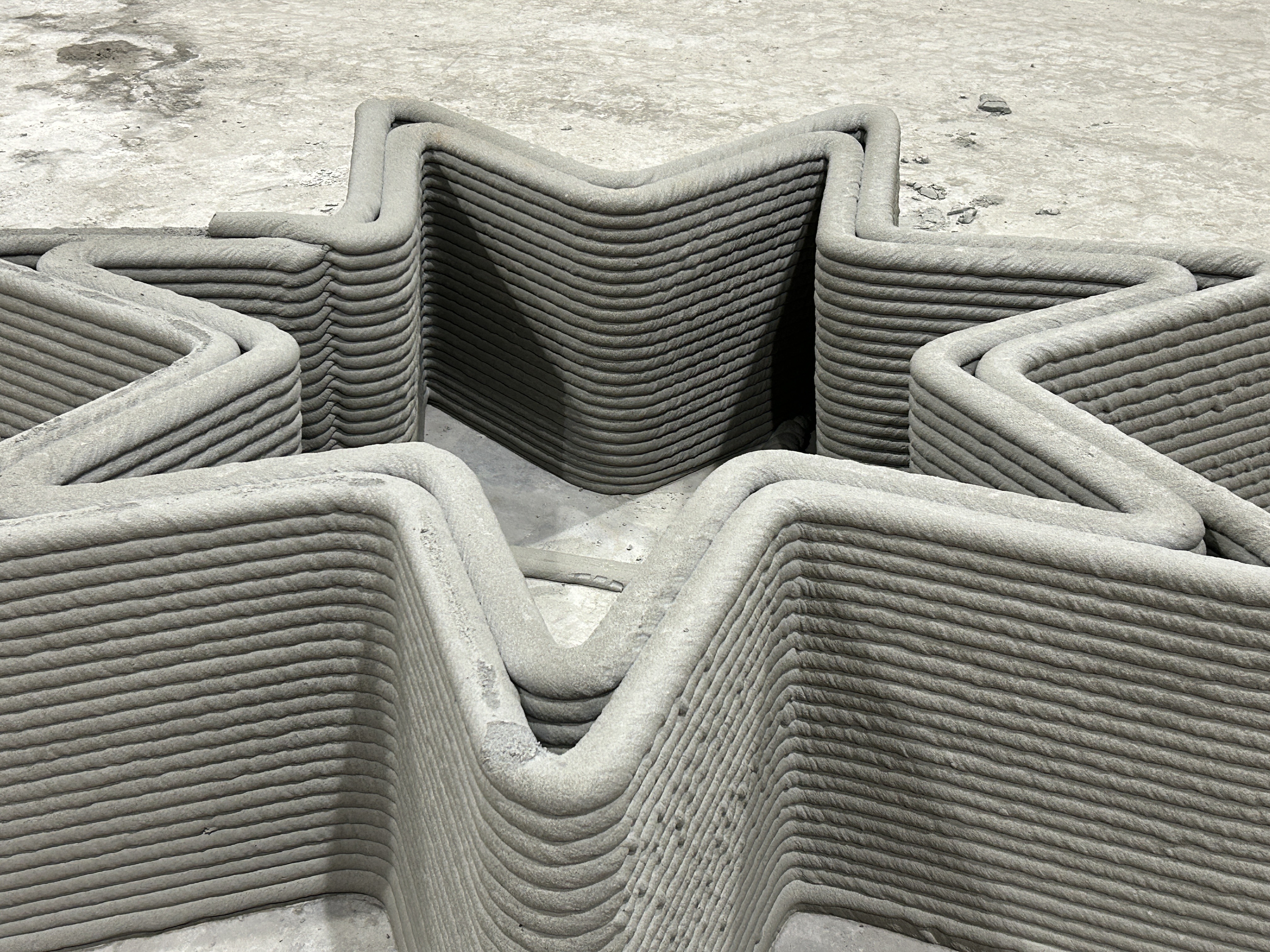

X-Hab 3D Concrete Printing

Systems For Sale

Learn How X-Hab 3D Concrete Printing is

Revolutionizing Construction

Download industry sheets with specs today:

MX3DP 3D Concrete Printer

Does location matter?

For our Mobile Expeditionary 3D Printer (MX3DP) system, not so much.

The MX3DP system is a compact, ruggedized robotic-arm style 3D printer on a continuous track mobile platform, complete with materials mixer, pumping system, wireless remote control and 24/7 remote monitoring and technical support.

The MX3DP system is designed and built to perform accurately and reliably in the most difficult conditions, including unimproved, challenging terrain, without the need for supporting heavy equipment or infrastructure in its setup or operation.

A 3D Concrete Printing Solution to Your Specs

The MX3DP system is designed to print structures up to 24 feet high, using its computer-controlled, 6-axis robotic arm in combination with the custom lift mechanism mounted on the mobile platform. It can also print up to 14 feet below grade.

The MX3DP comes equipped with all the necessary components to begin printing immediately, including:

- Material feed system

- Extrusion system

- Print heads

- Spare parts kit

- and much more

Mobile 3D Concrete Printing at the Ready

The MX3DP printer comes fully assembled and fits into a standard, 20-foot shipping container or flatbed trailer. It’s ready for immediate transport to the point of need virtually anywhere on the planet, whether it’s by:

- Truck

- Plane

- Helicopter

- Ship or barge

Once at the desired location, the printer can exit the container or trailer and move about the construction site under its own power. It’s also equipped with hydraulic lift capability for added reach and positioning.

At a Glance:

Hover over the images to learn more.

Rugged

X-Hab 3D's system is built for maximum reliability, versatility, and endurance, ensuring that it can perform under the most demanding conditions while delivering high-quality, 3D concrete structures wherever they are needed.

Mobile

X-hab 3D's mobility enables fast, autonomous, and resilient construction anywhere, from remote military bases to disaster-stricken areas and off-grid settlements, setting it apart from traditional stationary 3D printing systems.

Versatile

X-Hab 3D's mobile robotic system is far more than a 3D concrete printer - it's a multi-functional, semi-autonomous construction platform designed for diverse applications across military, disaster relief, and commercial sectors.

X-Hab 3D’s MX3DP Standard Components

Robotic-Arm Configuration

- Robotic arm with 6 axis rotation with 3.9+ meter reach (7th axis optional)

- Robot Controller with integrated software for code generation and slicing tools

- Robust control software and user interface

- Permanently mounted on mobile platform

Smart Nozzle

- Accelerant admixture control at print head is an option

- Flowrate control

- Start/stop

Mobile Platform

- Self-powered

- Continuous track mobile platform

- Stabilizer arms with self-leveling capability

- Hydraulic power unit and electric generator

- Custom lift mechanism

- Wireless tablet for remote control

Standard Support Services

- Digital Design Software

- Access to X-Hab 3D’s Digital Design Gallery

- Spare Parts / Repair Kit

- Training for four individuals

- Real-time virtual technical support 24/7/365

- Warranty: 1-year end-to-end warranty against manufacturing and design defects

Options

- Materials Mixer

- Pumping System

- Silo for Construction Material

- All hoses and feed lines for normal operation and for flushing cycles

- Extended Warranty

.jpg)

FS3DP: Precision 3D Concrete Printing for Controlled Environments

The FS3DP is a fixed-site 3D concrete printer designed for high-precision, repeatable, and fully automated printing in a controlled environment. Installed on a secure riser attached to the floor, it requires just a one-time setup and is ready for continuous operation with minimal intervention.

Rapid Setup, Maximum Flexibility

- One-time installation in just a few hours—permanently secured and always ready to print.

- Quick job preparation—load materials, connect, and start printing in about an hour.

- Designed for continuous operation, supporting both short runs and long production cycles.

Unmatched Design Freedom for Custom Projects

Unlike traditional pre-cast methods that require new molds for every variation, the FS3DP allows on-the-fly modifications through simple adjustments to the CAD file. This enables:

- Custom one-off designs without the time and cost of mold fabrication.

- Iterative development for research, prototyping, and material testing.

- Architectural and structural components with complex geometries and integrated features.

- Efficient production of modular and scalable elements for infrastructure, housing, and commercial projects.

Precision Printing, Every Time

- 6-axis robotic arm with a 3.9m reach enables intricate and variable designs.

- Controlled environment printing ensures material consistency and quality.

- Fully programmable automation for high repeatability across multiple runs.

Integrated Software for Seamless Execution

- Direct design-to-print workflow eliminates manual steps and complexity.

- Easy CAD file modifications for real-time adjustments.

- Supports both standard and fully customized builds with no added setup time.

The FS3DP is the ideal solution for pre-fabrication, advanced material research, custom architectural projects, and scalable production, delivering efficiency, flexibility, and precision in a controlled setting.

At a Glance:

Hover over the images to learn more.

Precision

Our stationary 3D concrete printer delivers precision with exact layer placement, uniform material flow, and minimal variance - perfect for complex, high-tolerance builds.

Consistency

Our printer ensures consistency, delivering uniform layer deposition, repeatable quality, and flawless builds.

Scalability

A stationary 3D concrete printer delivers scalability and mass customization, seamlessly scaling production while tailoring designs to unique specifications.

X-Hab 3D’s FS3DP Standard Components

Smart Nozzle

- Accelerant admixture control at print head is an option

- Flowrate control

- Start/stop

Robotic-Arm Configuration

- Robotic arm with 6 axis rotation with 3.9+ meter reach (7th axis optional)

- Robot Controller with integrated software for code generation and slicing tools

- Robust control software and user interface

- Mounted on stationary platform securely attached to the floor

Standard Support Services

- Digital Design Software

- Access to X-Hab 3D’s Digital Design Gallery

- Spare Parts / Repair Kit

- Training for four individuals

- Real-time virtual technical support 24/7/365

- Warranty: 1-year end-to-end warranty against manufacturing and design defects

Options

- Materials Mixer

- Pumping System

- Silo for Construction Material

- All hoses and feed lines for normal operation and for flushing cycles

- Extended Warranty

Upgrade How You Build

Find out more about our complete 3D concrete printing solutions

.png?width=2516&height=1448&name=ac823059-9afb-4267-88e6-db3466b4792c%20(1).png)

.png?width=1659&height=1260&name=103bc12f-42b8-45c2-8340-2db939598f8a%20(1).png)